สินค้าอยู่ในหมวด Freezer & IQF.

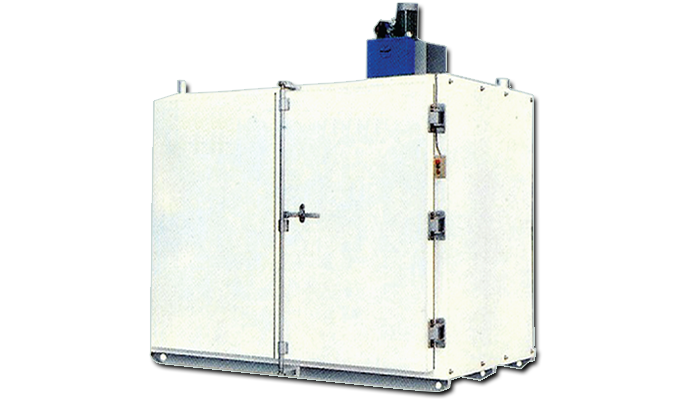

Contact Plate Freezer

Double contact plate freezing is a fast and economic way of freezing due to double contact with the product packaging.

| Model | CPF-750 | CPF-975 | CPF-1200 | CPF-1500 |

|---|---|---|---|---|

| Freezing Capacity Per Batch | 300 Tray / Batch | 390 Tray / Batch | 480 Tray / Batch | 600 Tray / Batch |

| Block WT. Gross | 750 kg / Batch | 975 kg / Batch | 1,200 kg / Brach | 1,500 Tray / Batch |

| Shrimp WT. Net (Headless) | 540 kg / Batch | 702 kg / Batch | 864 kg / Batch | 1,080 Tray / Batch |

| Shrimp WT. net (Head-on) | 390 kg / Batch | 507 kg / Batch | 624 kg / Batch | 780 Tray / Batch |

| Tray Size (L x W x t.) mm | 300 x 200 x 65 | |||

| Height | 1,650 mm | 2,000 mm | 2,365 mm | 2,850 mm |

| Length | 2,625 mm | |||

| Width | 1,530 mm | |||

| Weight | 1,500 kg | 1,800 kg | 1,970 kg | 2,200 mm |

| Refrigerating Capacity (kWr) | 50 | 65 | 77 | 96 |

| Freezing Time with Good contact | 120 minutes | |||

| Refrigerant | R-404a, R-507, or NH3 | |||

| Evaporating Temp. | -40℃ | |||

| No. of Freezing Stations | 10 | 13 | 16 | 20 |

| Type of Freezer | horizontal | |||

| No. of Freezing Plate | 11 | 14 | 17 | 21 |

| Dimension of Freezing Plate | 1,850 (L) x 1,120 (W) x 22 (T) mm | |||

| Space Between Freezing Plates | Max. 100 mm Min. 50 mm | |||

| Lift up System of Freezing Plate | Hydraulic Type, 2 HP. | |||

| Hose Materials | Stainless sus 304 | |||

| Surface moterial of cabinet | Int. & Ext. Colorbond-Coated steel sheet, Optional: Stainless steel | |||

| Insulating material of cabinet | Rigil foamed PU | |||

| Insulation Thickness | 75 mm | |||

Note :

- Other capacity and dimension are available. Please contact manufacturer.

- Specifications subject to change without notice.