สินค้าอยู่ในหมวด Freezer & IQF.

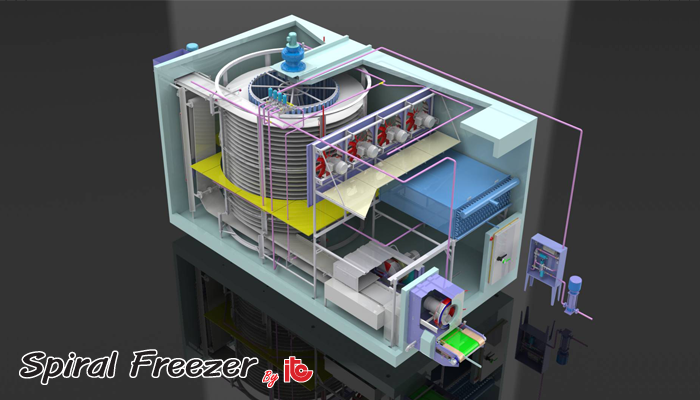

Spiral Freezer

Spiral Freezer ของเรามีคุณสมบัติพื้นฐานดังนี้

- ออกแบบที่แข็งแรงทนทานต่อการใช้งาน

- ให้ผลผลิตสูงจากการผนวกลมทั้งแนวตั้งและแนวนอน

- ทำงานต่อนื่องได้มากกว่า 48 ชั่วโมง ก่อนที่จะต้องทำการละลายน้ำแข็ง

- ทุกอุปกรณ์สามารถทำความสะอาดได้ง่าย

- เชื่อมเต็มแผ่นสแตนเลสเพื่อปิดผิวภายใน

- ผิวภายนอกทำจากแผ่นคัลเลอร์บอนด์ หรือแผ่นสแตนเลส (option)

- ขับเคลื่อนโดยตรงด้านบนซึ่งช่วยลดความสกปรกจากการใช้โซ่ขับเคลื่อน

| Model SPFR | 16D-28-4 | 20D-26-4 | 24D-29-4 | 28D-26-4 | 36C-24-5 | 42C-28-5 |

|---|---|---|---|---|---|---|

|

Capacity For Chicken 85℃ (Mt/Hr) Chicken Loading 5.5 kg/m2 |

400 | 600 | 980 | 1,200 | 1,590 | 2,100 |

| Capacity For Cook Shrimp. 10℃ (Mt/Hr) Shrimp Loading 5.0 kg/m2 | 360 | 540 | 890 | 1,100 | 1,450 | 1,900 |

| Overrall Belt Width (mm) | 406 | 508 | 609 | 710 | 914 | 1,067 |

| Number of Teir | 28 | 26 | 29 | 26 | 24 | 28 |

| Max. Product clear Height (mm) | 70 | 70 | 70 | 70 | 90 | 90 |

| Usable Blt Area/Tier (m2) | 2.61 | 4.20 | 6.16 | 8.49 | 14.28 | 19.60 |

| Total Usable belt Area (m2) | 73.08 | 109.20 | 178.64 | 220.74 | 342.72 | 548.80 |

| Refrigeration System | "Ammonia or HFC" Pump Circulation, Flooded or DX | |||||

| Evaporating Temperature | -40℃ | |||||

| Base Load (kWr) | 45 | 55 | 65 | 70 | 100 | 120 |

| Product Load (kWr) | 63 | 94 | 153 | 187 | 247 | 327 |

| Total Cooling Required (kWr) | 108 | 149 | 218 | 257 | 347 | 447 |

| Main Drive (kW) | 2.2 | 3.7 | 3.7 | 5.5 | 7.5 | 11 |

| Total Connecting Power (kw) | 15 | 20 | 28 | 30 | 55 | 75 |

| Enclosure Length (m) | 5.8 | 7.1 | 8.4 | 9.7 | 10.3 | 12 |

| Enclosure Width (m) | 3.6 | 4.5 | 5.2 | 5.8 | 6 | 6.8 |

| Enclosure height (m) | 4.2 | 4.5 | 4.8 | 4.5 | 4.9 | 5.4 |

| Outfeed Length/Height (m) | 0.3/3.65 | 0.3/3.61 | 0.3/3.91 | 0.3/3.61 | 0.3/4.01 | 0.3/4.51 |

| Infeed Length/Height (m) | 1.2/0.76 | 1.2/0.91 | ||||

| Appx. Weight (kg) | 7,000 | 9,000 | 13,000 | 14,000 | 18,000 | 26,000 |

Note :

- Other capacity and dimension are available. Please contact manufacturer.

- Cooling required capacity and connecting power will be varied depending on type of products.

- Specifications subject to change without notice.

ITC’s Spiral Freezer, a host of many convenient features, evolves into a distinct and one of a kind industrial freezer built in a high freezing technology.

Throughout the years, ITC’s freezer uses a unique PLC Touch Screen Control System, which contributes a significant advancement in fast operation system. Also, the screen control is really easy to use since all data (e.g. temperature, pressure, and time) are visible on the screen.

The Freezing capability of spiral freezer is extremely fascinating as it can swiftly pull the freezing temperature down to -40℃. This can assure the products are well preserved to maintain their quality and texture as well.

Freezing process yields mix vertical and horizontal airflow resulting the products’ quality and texture to be well preserved. The machine has two distinct freezing methods. One is the pre-freeze crust coating and drying method held in front of the feeding pathway, while the other is final freeze coating method activating at lengthy spiral drum’s body.

Moreover, recirculation type CIP system (optional) is an essential feature applied in spiral freezer because of its unique clean system. Since the conveyor relies on the type of products, the spiral conveyor belt is optionally available upon request. Also, the panel wall are available either stainless steel or color bond sheet type.

ITC’s Spiral Freezer has various models such as SPFR 16D-29-4, SPFR 20D-26-4, SPFR 24D-29-4, SPFR 28D-26-4, SPFR 36C-24-5 and SPFR 42C-28-5. Each model is di erent in products’ weight loads.

With its high productiveness and high e ciency, ITC’s Spiral Freezer undeniably has the edge over other competitors.